Inside Look at SCOTT`s Carbon Expertise

Carbon has been used for more than a decade in bicycle frames. What exactly makes the difference in carbon engineering? Learn more about the process that has made SCOTT the forerunner in the development of "black gold."

SCOTT was one of the first brands to use carbon fiber extensively in its bicycle frames. Since then we have strived to improve carbon technology, always aiming to make lighter, more robust, and more durable products. With this in mind, SCOTT has been a forerunner in carbon process development with regards to manufacturing practices that are precise, repeatable, and that minimize waste. SCOTT engineers continue to work with independent testing laboratories and engineering universities not only to maintain SCOTT’s rigid standards within carbon manufacturing, but also to foster new developments and advance its carbon expertise.

We invite you to get a inside look at our development process, and to learn how we develop the worlds most abundant element into race ready frames. Learn more on our new microsite and with our carbon movie, both provided in twelve languages:

http://carbonexperts.scott-sports.com/en/index.html

From a pure fiber...

Carbon is not Carbon. While there is the well-known HMF fiber, we use the higher performing HMX fiber for all our high-end frames. HMX is 20 percent stiffer than HMF. This unique material allows SCOTT engineers to create incredibly light bikes with excellent riding characteristics.

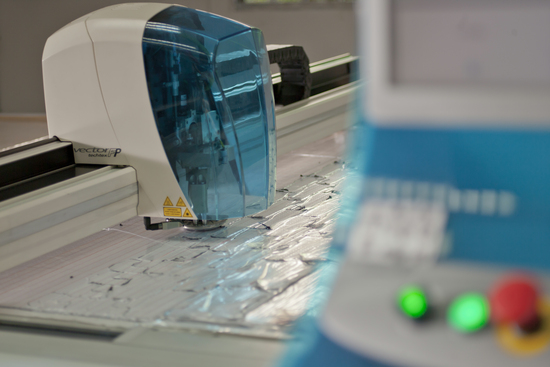

...preparing the layers...

There are over 200 pre-prepared pieces of all sizes that are necessary to construct a single bicycle frame. Precision over these many repetitions is key to success. Without expert preparation a structure is not 100% managed for quality.

IMP - Preforming...

IMP, or Integrated Molding Process, is a process developed by SCOTT engineers that allows for multiple tubes to be created in a single step while managing the layers completely. When the carbon fiber is fully optimized then less of it can be used resulting in a lighter structure.

Machining and fine tuning...

The Integrated Molding Process is the result of our 20+ year commitment to carbon fiber as a frame material. In order to assemble a precise final product, areas of the frame with critical tolerances are tuned so that the frame is finished well without any compromises.

Intense testing...

Frames are put through rigorous testing during Quality Control evaluations. Fatigue tests are performed in order to gauge the long-term durability of the finished product. The base lines a frame must endure are more than 200x the amount a human being can inflict upon the structure.

...to a race-ready carbon frame

Every great form deserves color and design. In order to achieve the rich appearance of SCOTT bicycles we choose high quality enamels and choose invoking designs to give the product more appeal. Each decal is installed by hand and a durable clear coat is applied to protect the finish.

Watch the whole process: